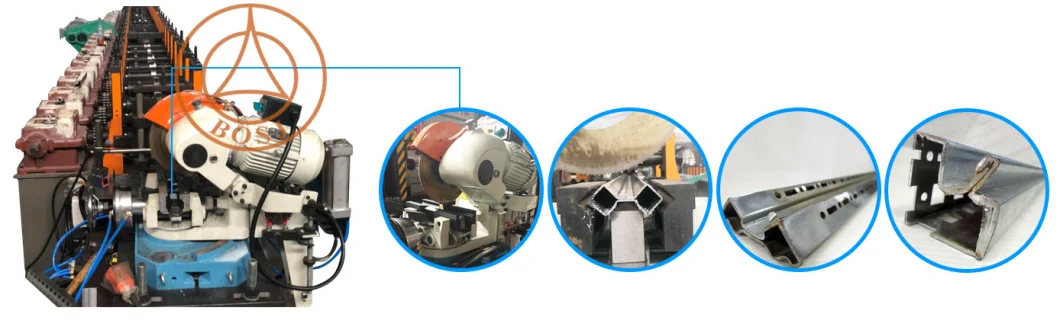

Electric cabinet Roll forming machine

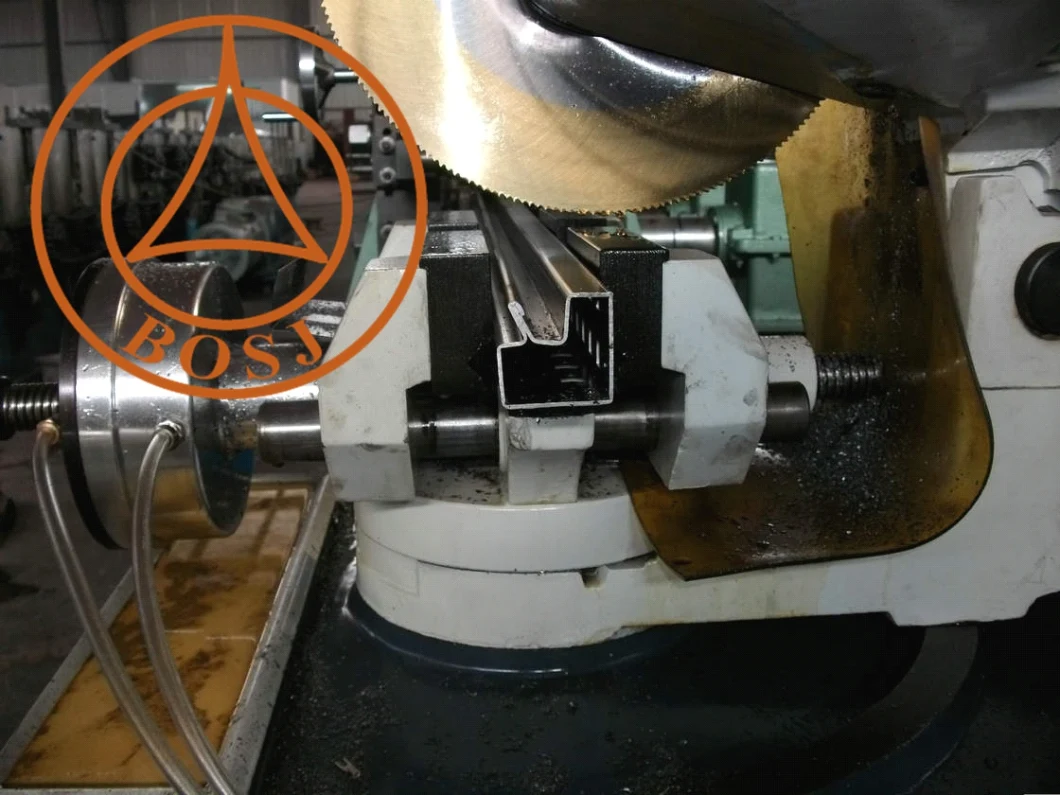

Electric cabinet rack and frame design,two production lines includes welding,roll forming,saw cutting technology.

If you would like the electric cabinet Enclosures in either 2D or 3D for either AutoCAD Electrical or elecworks,BOSJ offer you all machine solutions.

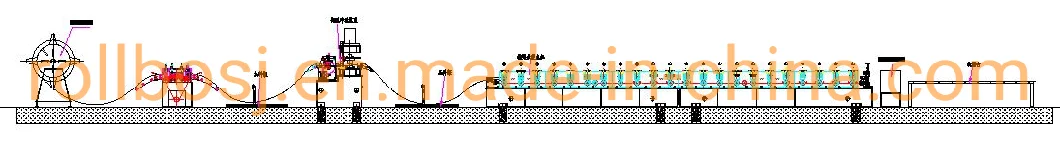

Production Process

Decoiler --- straighten/leveler --- servo feeder--- punching -- forming -- cutting --- colletcion

Technical parameter

| NO. | Item | Unit | Parameter | Remark | |

| 1 | Material | Type | galvanized sheet,mild steel,etc, | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 1.5 | customized | ||

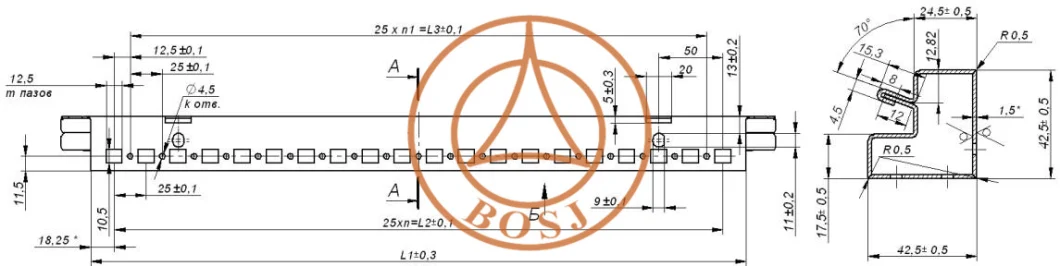

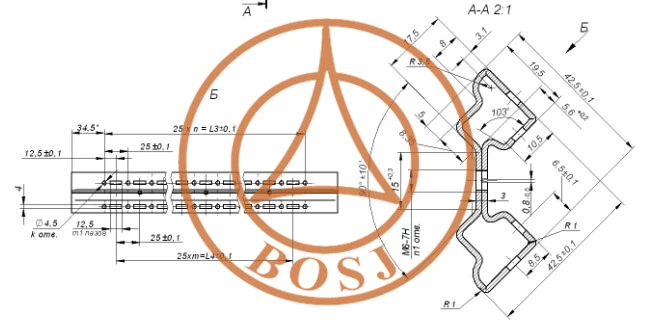

| 2 | Profile sizes | mm | See Figure | ||

| 3 | Production speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr15 quenching treatment | |||

| 5 | Drive type | Gearbox driven | |||

| 6 | Motor Power | kw | About 40 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 35X4X3.9 | ||

Main machine technical parameter

Passive de-coiler Structure: passived de-coiler

Width of coil:100~250mm,thickness:1.5mm

ID:φ508mm;OD:ф480-520 mm;

Max. OD:φ1200mm;Capacity:≤2.0T

Leveler Straightening rollers:up 4/down 5 rollers

Leveler range:Max. Coil width:220mm Max coil thickness 1.5mm

Servo Feeding machine

Function:material feeding

Servo motor power:3kw

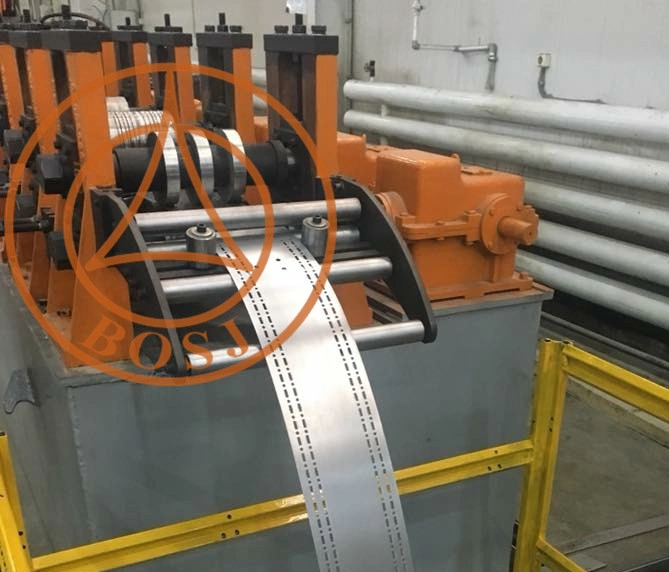

Roll Forming Machine

Forming stations:26 stations

Max feeding width:220mm

Roller axis diameter:¢60mm,,Material 40Cr

Roller material :GCr15,quenching treatment,Hardness HRC56-62º

Motor power:22kw

Profile drawings

Thank you for your Attention!

Please send your inquiry to us.

You can click"Send" Now!